Introduction

The Rotary Inverted Pendulum, otherwise known as a Furuta pendulum, is a variation on a classic problem in the area of control system, the pendulum on a cart. Instead of being attached to a moving cart constrained to move linearly in only one dimension, the Furuta pendulum’s “cart” is a rotary object. The Furuta pendulum is an example of a nonlinear system, which also makes it more difficult to maintain upright. It is used to verify the performance of control algorithm techniques, of which can later be used to control more complicated systems, such as an aircraft flight. For an example of a Furuta pendulum, you can see a video of it here.

Our objectives were as follows:

- Design the mechanical system, which composed of the pendulum, the arm, and the box

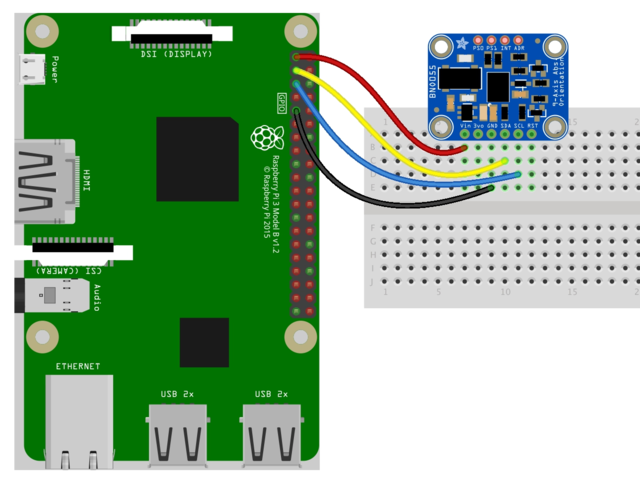

- Read real-time data from the IMU

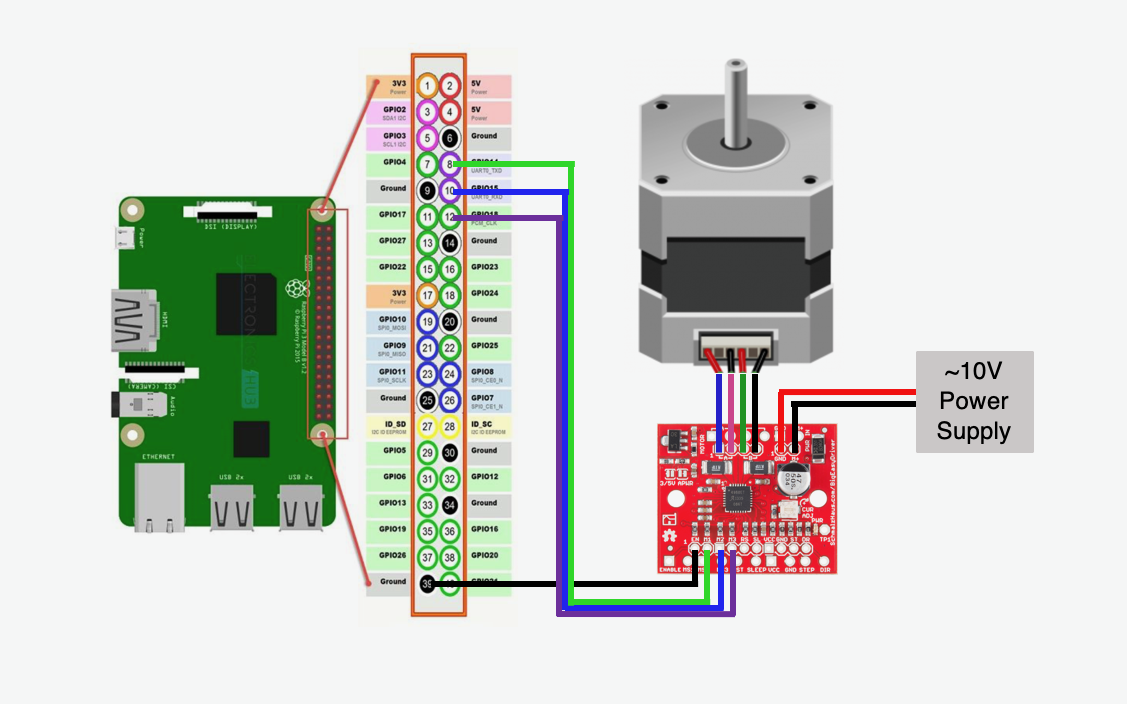

- Design a controller to output the desired position of the stepper motor

- Control the stepper motor with accuracy

Design

Pendulum Assembly

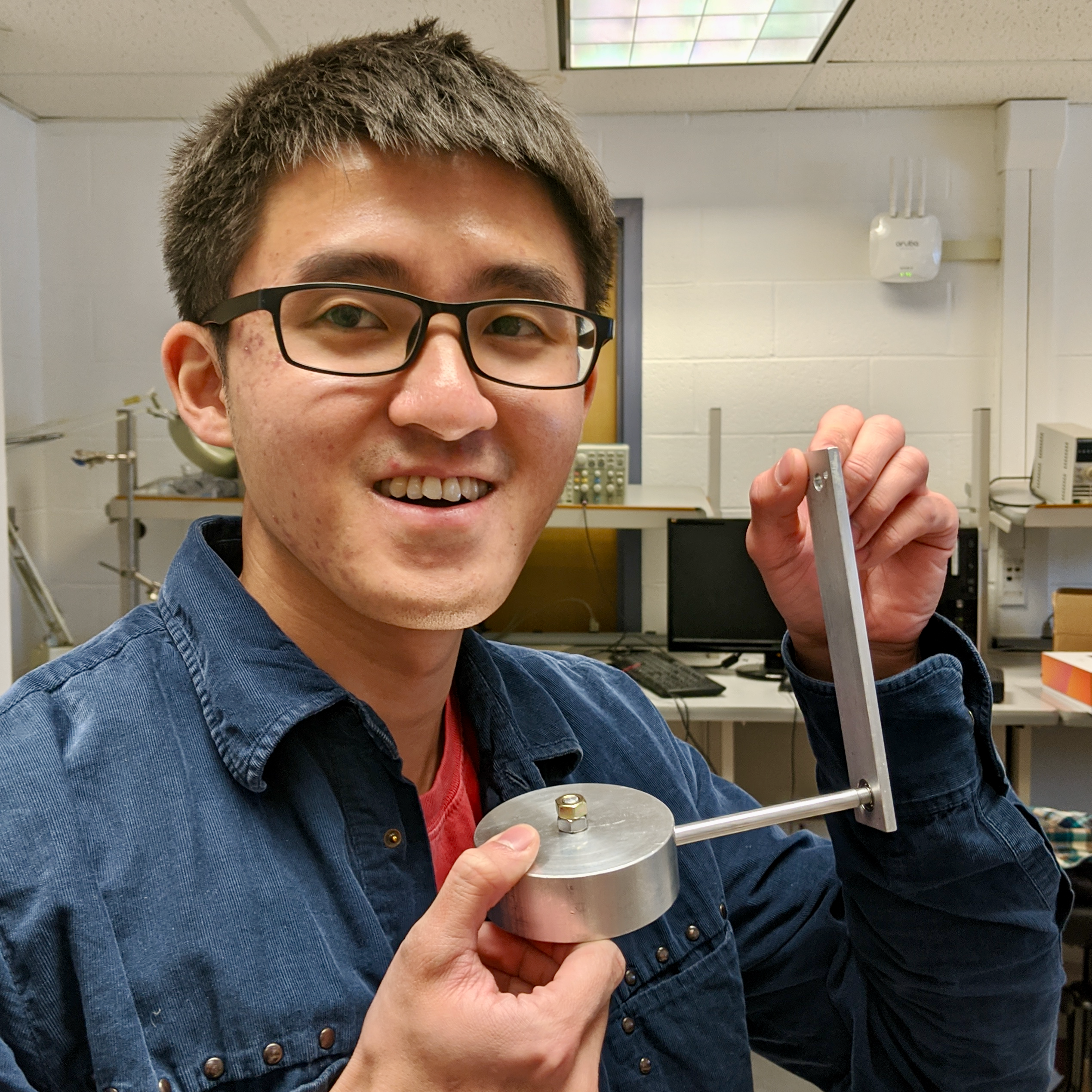

We decided to make our system primarily out of aluminum instead of 3D-printing all of the parts. The primary reason for this was that we wanted a very smooth rotation at the point of contact of the pendulum, allowing it to spin freely. The obvious answer for doing this was to use a ball bearing; rolling friction is lower than sliding friction. The system would also be more robust if made of metal, and it would be easier to attach with the shaft of the stepper motor. We purchased aluminum bars and rods from McMaster-Carr so that we could get to machining quickly. We used aluminum because it is easier to machine aluminum than it is to machine steel, and our application wasn’t subject to any high stresses that aluminum could not handle.

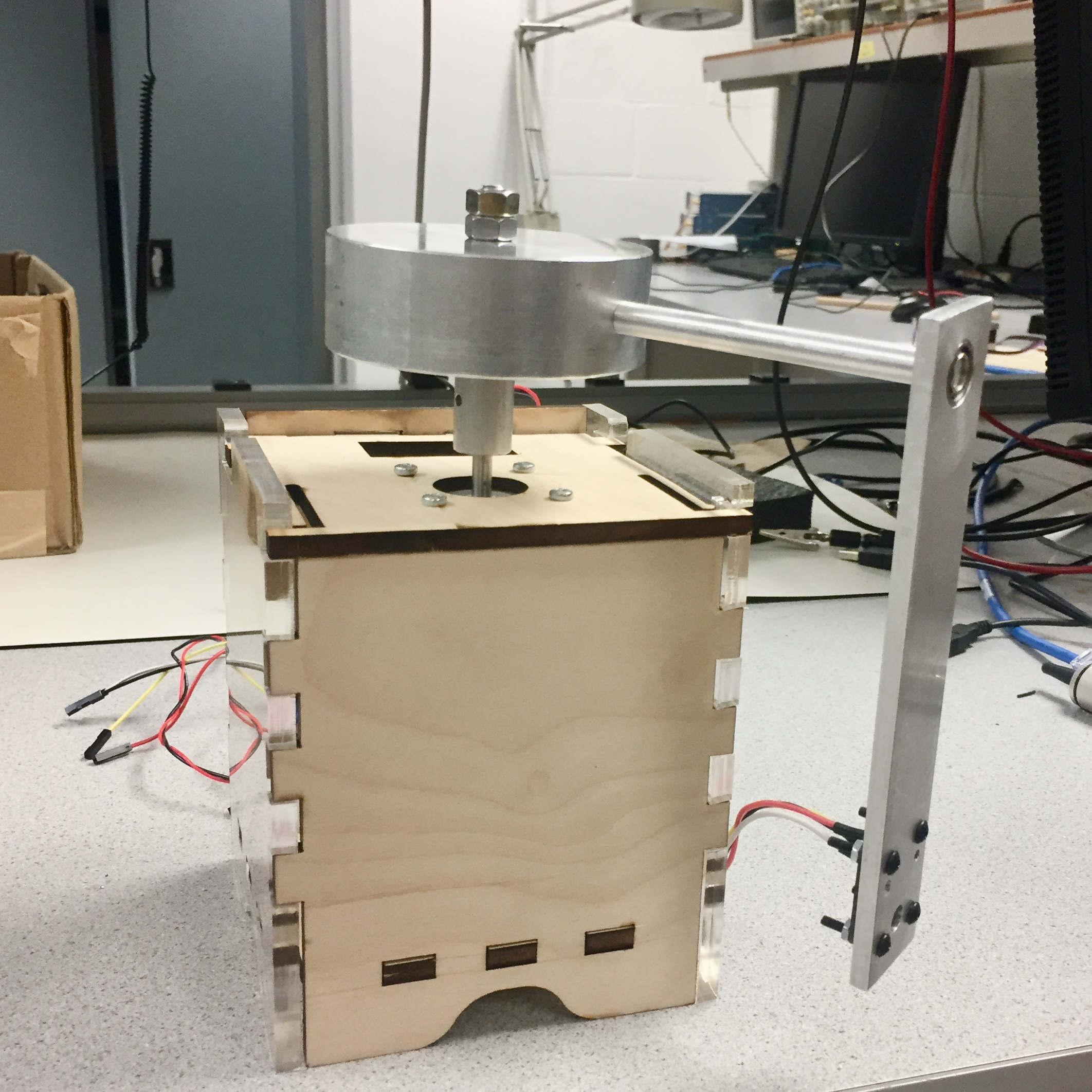

To the left is our initial CAD of the system. The entire pendulum assembly sits on top of a laser cut box so that the pendulum could be made longer. Thankfully, this ended up not being an issue, and you can see more photos of the machined parts below!

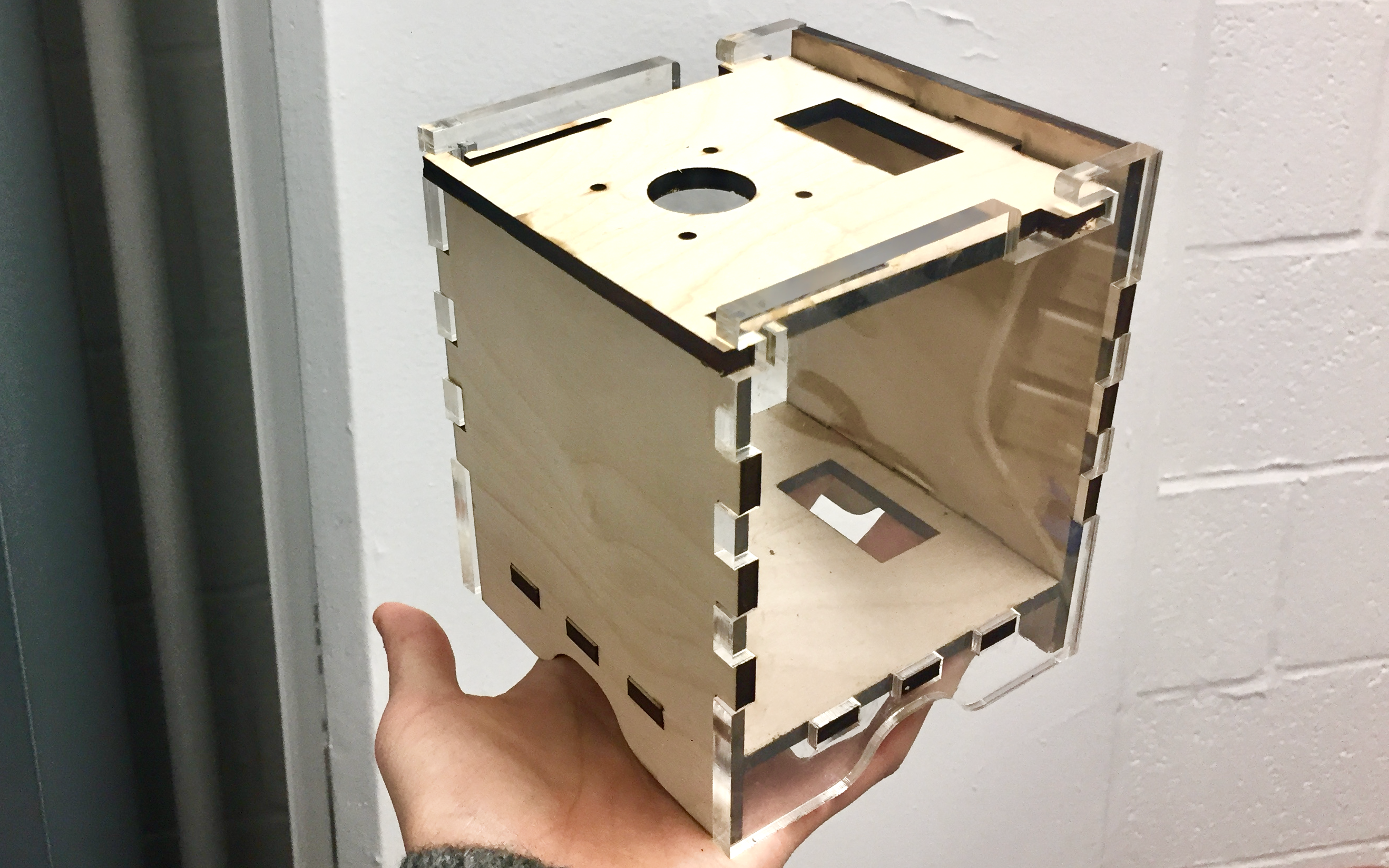

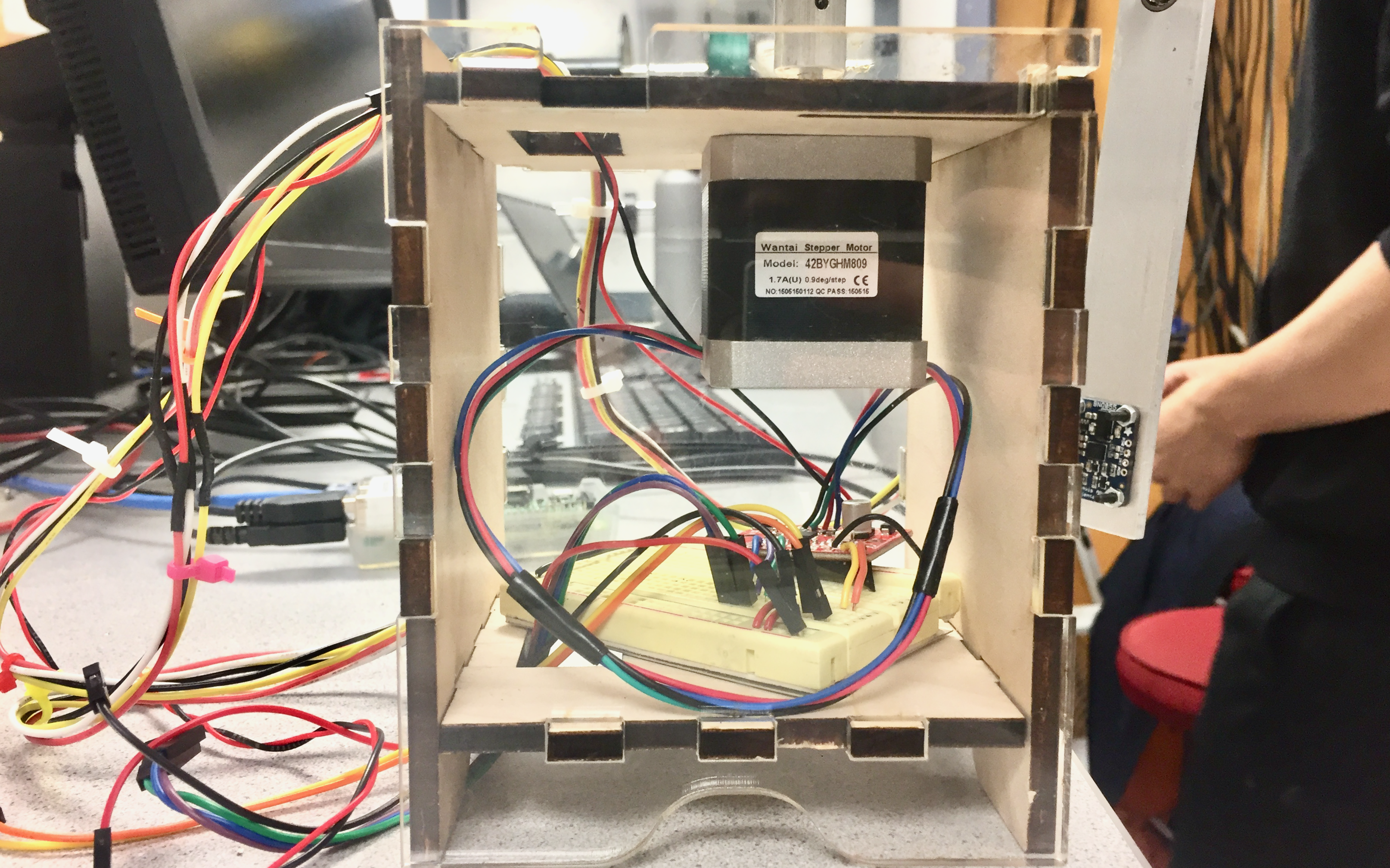

Housing

We decided to laser-cut a box to hold the breadboard with the motor driver and hide the excess wires. We originally wanted the box to be completely made of wood, but we ended up using clear acrylic for the sides, which ended up looking really cool.

Originally, we planned on having the motor sit on top of the box to provide enough height for the pendulum to swing around, but the vibrations from the stepper motor required us to have the motor clamped or fixed in some way. We later cut out holes on the top of the box so that we could screw on the motor from the inside of the box.